Unlocking CAE: How Simulation Drives Smarter, Safer, and Optimized Designs

In modern design and manufacturing, businesses need not only creative ideas but also products that are sustainable, safe, and cost-efficient. To achieve this, engineers must simulate, validate, and improve designs from the early stages. This is precisely the role of CAE (Computer-Aided Engineering) – a computer-assisted engineering tool that has become an essential trend across all industries.

1. What is CAE?

CAE involves using software and computer tools to simulate, analyze, and optimize products. Instead of creating multiple physical prototypes for testing, engineers can validate products in a virtual environment.

Thanks to CAE, businesses can:

- Predict how products respond to physical factors such as force, heat, vibration, and fluid flow.

- Identify and resolve design issues at the earliest stages of concept development and product design.

- Save time and reduce product development costs.

- Enhance product quality, durability, and safety.

CAE can be considered a digital laboratory – a place where all engineering hypotheses are tested before being applied in reality.

2. Key Simulation Domains in CAE

2.1. Structure & Durability Simulation

This domain focuses on analyzing the structural behavior of products—from stiffness and deformation to load-bearing capacity and lifecycle durability.

Key Highlights:

- Evaluate stress, strain, and load-bearing performance under various operating conditions.

- Perform fatigue and durability analyses, predicting locations susceptible to cracking or failure.

- Simulate real-world scenarios such as collisions, vibrations, or cyclic loading to ensure design reliability.

- Support structural optimization to reduce weight while maintaining stiffness, safety, and performance.

Representative Software: SIMULIA Abaqus, ANSYS Mechanical, Nastran, SIMULIA fe-safe

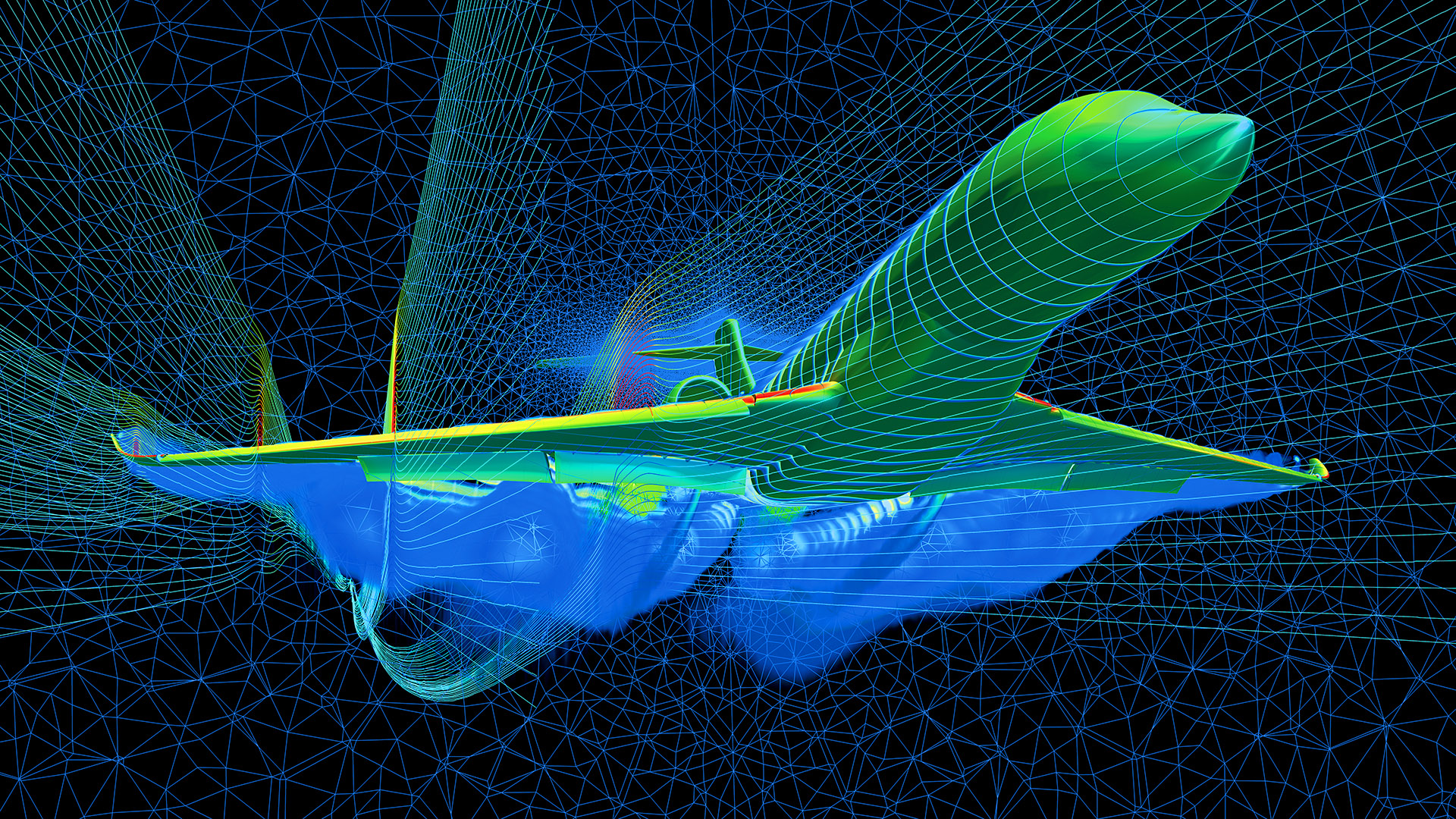

2.2. Fluids / Computational Fluid Dynamics (CFD) Simulation

This domain focuses on the behavior of fluids (liquids, gases, or plasmas) at rest or in motion, including the forces acting on them.

Key Highlights:

- Simulate flow in pipes, combustion chambers, rotors, or hydraulic systems.

- Support aerodynamic analysis and airflow simulation in automotive, aerospace, and energy applications.

- Minimize physical testing in wind tunnels or experimental facilities through accurate numerical simulation.

- Analyze steady, transient, or complex flows across a wide range of real-world conditions.

Representative Software: SIMULIA Fluid Dynamics Engineer, XFlow, PowerFLOW, Fluent, Star-CCM+

2.3. Electromagnetics Simulation

This domain focuses on the nature and interaction of static and dynamic electric and magnetic fields in electronic and electromechanical systems.

Key Highlights:

- Analyze emission, guidance, reception, and interaction of electromagnetic waves in telecommunications, radar, and navigation systems.

- Design antennas, electromagnets, motors, generators, transformers, and charged-particle devices.

- Optimize electromagnetic systems for high-frequency applications (CST Studio Suite – radar, antennas, communications) and low-frequency applications (Opera – electromagnets, medical devices, electrical machines).

Representative Software: CST Studio Suite, Opera FEA, JMAG

2.4. Multibody Dynamics Simulation

This domain focuses on predicting the motions of systems composed of rigid and flexible bodies, from full system behavior to detailed component interactions.

Key Highlights:

- Simulate movement, collisions, and interactions between components in complex mechanical systems.

- Analyze vibrations, noise, and load-bearing behavior of moving mechanisms.

- Support system-level performance prediction and provide dynamic load data for detailed FEA studies.

- Widely applied in automotive, rail, aerospace, and wind energy sectors.

Representative Software: Simpack

3. Benefits of Using CAE Software

3.1. Reduces Product Development Costs

One of the biggest benefits of CAE is significantly lowering R&D costs. Instead of building multiple physical prototypes, engineers can simulate dozens of scenarios on a computer, reducing material waste, labor, and testing cycles. CAE allows businesses to move from concept to physical prototype faster, cheaper, and reliably.

3.2. Shortens Product Development Cycles

In a competitive market, faster product launches can determine success. CAE enables engineers to test and optimize designs quickly, instead of spending weeks or months on traditional experiments. This shortens product development cycles, allowing businesses to enter the market sooner and keep up with technology trends.

3.3. Increases Design Accuracy and Reliability

CAE not only “tests” designs but also predicts product behavior under extreme conditions: high pressure, strong vibrations, sudden temperature changes. Detailed simulation data helps engineers make accurate design decisions, ensuring products operate reliably and last longer – crucial in industries like automotive, aerospace, and medical devices.

3.4. Fosters Innovation

A key advantage of CAE is freeing designers’ creativity. With lower testing costs, engineers can experiment with bold ideas. CAE provides a safe virtual environment to evaluate new designs, helping businesses create innovative and distinctive products.

3.5. Enhances Sustainable Competitive Advantage

All of the above – cost savings, faster development, improved accuracy, and innovation – contribute to a lasting competitive edge. Companies using CAE effectively can improve internal processes and deliver higher-quality products faster, better suited to market needs.

4. Applications of CAE in Modern Industry

4.1. Automotive Industry

CAE is essential for ensuring both performance and safety. Engineers use crash simulation software to test driver and passenger protection in various scenarios. Aerodynamics are analyzed to reduce drag, improve fuel efficiency, and enhance driving experience. CAE also optimizes engine, suspension, and chassis designs, creating vehicles that are durable and environmentally friendly.

4.2. Aerospace Industry

With strict safety and efficiency requirements, aerospace heavily relies on CAE. Engineers simulate and analyze wing and fuselage structures, as well as jet engines, under pressure, vibration, and high temperatures. CAE predicts material behavior in harsh flight conditions and helps reduce structural weight while maintaining strength, ensuring operational safety and reducing fuel costs.

4.3. Construction and Architecture

In construction, CAE helps engineers calculate and simulate structures’ load-bearing capacity against natural forces like strong winds, earthquakes, or extreme loads. Structural simulation predicts building lifespan, material suitability, and optimizes construction costs, ensuring safe and sustainable infrastructure.

4.4. Electrical and Electronics Industry

CAE is vital for designing increasingly compact and complex electrical and electronic devices. Software can simulate heat distribution on circuit boards, check current flow through components, and predict electromagnetic effects. This helps engineers detect overheating, short circuits, or performance degradation early, improving reliability and product lifespan.

4.5. Medical Industry

In healthcare, CAE supports the development of precise and safe medical devices. Mechanical and biological simulations validate the durability of implants, or analyze blood flow through stents to ensure stable operation. This shortens clinical testing and ensures devices meet international standards before market release.

5. Future Trends of CAE

Today, CAE goes beyond simulation thanks to emerging technologies:

- Artificial Intelligence (AI): Learns from previous simulation data to predict results faster and reduce computation time.

- Cloud Computing: Enables engineers in different locations to collaborate on simulations while handling complex data.

- CAD/PLM Integration: CAE is increasingly integrated with CAD (design) and PLM (product lifecycle management), creating a seamless workflow from concept to production.

Conclusion

CAE has become a crucial platform in modern product development. From automotive and aerospace to construction, electronics, and healthcare, it shortens design time, improves quality, reduces testing costs, and opens opportunities for innovation.

In the digital transformation era, businesses leveraging the power of CAE gain a sustainable competitive advantage.

👉 If your company is looking for suitable CAE solutions or wants advice on integrating CAE with CAD and CAM in your product development workflow, contact New System Vietnam (NSV). Our team of experts is ready to accompany you on your journey of innovation and engineering design optimization.