What are CAD, CAM, CAE, and PLM? Decoding the "Technology Quartet" in Modern Manufacturing

If you're new to the world of engineering or manufacturing, you've likely come across acronyms like CAD, CAM, CAE, and PLM. These terms may sound complex at first, but in reality, they refer to powerful tools that make product design, manufacturing, and management easier, faster, and more accurate.

In this article, NSV will break down each of these technologies in a simple and easy-to-understand way so you can clearly see their roles in modern industry.

1. CAD - Computer-Aided Design

CAD (Computer-Aided Design) refers to software that allows engineers and designers to create 2D technical drawings or 3D models on a computer.

Instead of drawing by hand—which is time-consuming and error-prone—CAD enables precise detailing, zooming in/out, rotating models, and even simulating how parts fit together.

Example:

When designing a new car part, an automotive designer uses CAD to create the model, test angles and dimensions, and ensure it fits properly before moving to production.

At NSV, CATIA 3DEXPERIENCE is our key CAD solution, ideal for designing large, complex mechanical components that require high precision — particularly in industries such as aerospace, automotive, and industrial machinery manufacturing. CADmeister is perfect for mold and precision machining design, while CADdoctor ensures seamless 3D data translation and validation across different CAD systems.

For 2D design, DraftSight offers a cost-effective, flexible option. Popular software like AutoCAD, Creo, and SolidWorks remain widely used in small to medium-sized businesses due to their user-friendly interfaces.

2. CAM – Computer-Aided Manufacturing

CAM (Computer-Aided Manufacturing) is the next step after CAD. It converts digital designs into physical products by automating machines such as CNCs, milling machines, and lathes.

CAM reads the CAD model and automatically calculates the necessary tool paths, cutting speeds, and machine movements. This ensures high precision and speed in production.

Example:

Once a machine part is designed in CAD, a CNC machine uses CAM to manufacture it with minimal manual intervention.

NSV offers CAM-TOOL, known for its advanced toolpath programming tailored for mold making and complex geometries. DELMIA, part of the 3DEXPERIENCE platform, supports full production simulation—from planning to shop floor execution. Meanwhile, VERICUT validates and optimizes CNC codes, reducing risks in real-world machining.

Other widely used CAM tools include Mastercam, NX CAM, and Fusion 360, favored by small and mid-sized manufacturers for their intuitive interfaces and device compatibility.

3. CAE – Computer-Aided Engineering

CAE (Computer-Aided Engineering) is used to simulate and analyze product performance before manufacturing. It helps test various technical properties, such as:

- Structural strength and stress

- Motion and collision behavior

- Heat and thermal effects

- Fluid flow within systems

CAE enables engineers to detect design flaws and optimize products for durability, safety, and efficiency.

Example:

Before producing a jet engine blade, engineers use CAE to simulate wind pressure and ensure the blade won’t break under stress.

NSV offers SIMULIA on the 3DEXPERIENCE platform—a powerful suite for advanced simulations. Key tools include Abaqus (structural analysis) and CST (electromagnetic simulation), helping engineers refine designs early in the process. Additionally, JMAG specializes in electromagnetic simulation for motor and electromechanical device design.

Well-known CAE tools like ANSYS, Altair, and COMSOL are also widely adopted, especially in industries requiring high-level mechanical, thermal, or electromagnetic analysis.

4. PLM – Product Lifecycle Management

PLM (Product Lifecycle Management) helps manage a product’s complete journey—from initial concept through design, manufacturing, quality checks, maintenance, and eventual retirement.

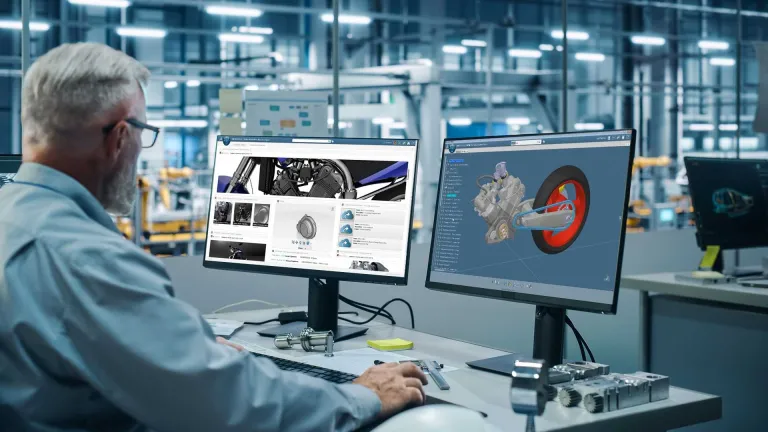

PLM systems organize all related information, data, and workflows so teams across departments can collaborate efficiently without confusion or data loss.

They also track version history, enable remote teamwork, and ensure information security.

Example:

In a smartphone company, PLM manages everything—from design specs and component production to assembly, quality control, market release, and even after-sales service.

NSV provides the 3DEXPERIENCE Platform, which connects design, simulation, manufacturing, and data management in one seamless ecosystem. ENOVIA serves as the core PLM tool, managing documents, product lifecycles, and cross-team collaboration—ensuring consistency and version control.

Other widely used PLM solutions include Teamcenter, Windchill, and Aras Innovator, ideal for enterprises needing deep integration with ERP or MES systems.

Conclusion

As modern manufacturing grows more complex and demands higher levels of quality, speed, and collaboration, understanding CAD, CAM, CAE, and PLM—and how they work together—empowers businesses to improve technical efficiency, optimize resources, and shorten time-to-market.

These technologies are not isolated; they form a continuous workflow—from design and simulation to production and full product lifecycle management—forming the backbone of digital transformation in today's industrial landscape.

🔎 You may also like:

👉 CAD Guide for Beginners: Simple to Understand, Easy to Use, Practical to Apply

👉 Comparing CAD Software for the Manufacturing Industry

👉 What is CAM? Applications and Roles in Modern Manufacturing