What is CAM? Applications and Role in Modern Manufacturing

In the era of smart manufacturing, reducing production time, improving quality, and minimizing errors in CNC machining are key factors for businesses to maintain a competitive edge. If CAD helps design products, then CAM acts as the “bridge” that transforms 3D models into reality on CNC machines. So, what exactly is CAM, what benefits does it offer, and which software solutions are the most popular today? Let’s explore in detail with NSV.

1. What is CAM?

CAM (Computer-Aided Manufacturing) is a computer-assisted manufacturing technology that converts 3D designs into direct control commands for machines such as CNC, lathes, milling machines, or 3D printers. If CAD is where product ideas take shape, CAM is the bridge that turns those ideas into tangible products on the production line.

Today, CAM goes beyond generating machine code. It also integrates simulation, analysis, and optimization capabilities. This allows businesses to automate machining processes, optimize toolpaths, minimize human errors, reduce production time, and improve product quality at a more cost-effective level.

2. Popular CAM Software Today

In mechanical machining, CAM software is no longer just a tool for generating toolpaths. Depending on production requirements, CAM solutions have evolved into various categories, from optimizing complex mold surfaces and verifying machining processes to managing entire production lines. Each type has its own strengths, helping businesses save time, reduce risks, and enhance efficiency.

2.1. CAM for Mold Making and Complex Parts

These CAM tools are widely used in mold manufacturing, curved surface machining, and high-precision components. They support 3–5 axis machining, enabling handling of complex surfaces that basic software cannot manage. They are top choices for mold makers, aerospace components, and medical devices.

Key Features:

- High-precision machining with multi-axis support (3–5 axes)

- Strong in handling curved surfaces, deep cavities, and complex parts

- Optimizes machining time and reduces errors in mold production

Representative Software:

- Cam-Tool: Specialized in mold machining, known for exceptional precision and smooth 5-axis machining. Trusted by many Japanese manufacturers.

- PowerMill: Strong in complex machining programming, popular in mold and aerospace industries.

- HyperMill: Supports diverse machining strategies, particularly effective for High-Speed Cutting (HSC).

2.2. Basic CAM – Suitable for Standard Machining

Basic CAM software is typically used by small and medium enterprises or for education and training. It supports 2D, 2.5D, and partial 3D machining, meeting basic cutting, milling, and turning needs. Its advantages include user-friendly interface, reasonable cost, and accessibility for beginners.

Key Features:

- User-friendly, easy to learn and deploy

- Suitable for simple, high-volume parts

- Large user community with extensive guides

Representative Software:

- Mastercam: Globally popular, strong in 2D/3D machining, with many post-processor options

- Fusion 360: Integrated CAD/CAM at low cost, ideal for startups and education

- SolidCAM: Excels in turning-milling integration within SolidWorks

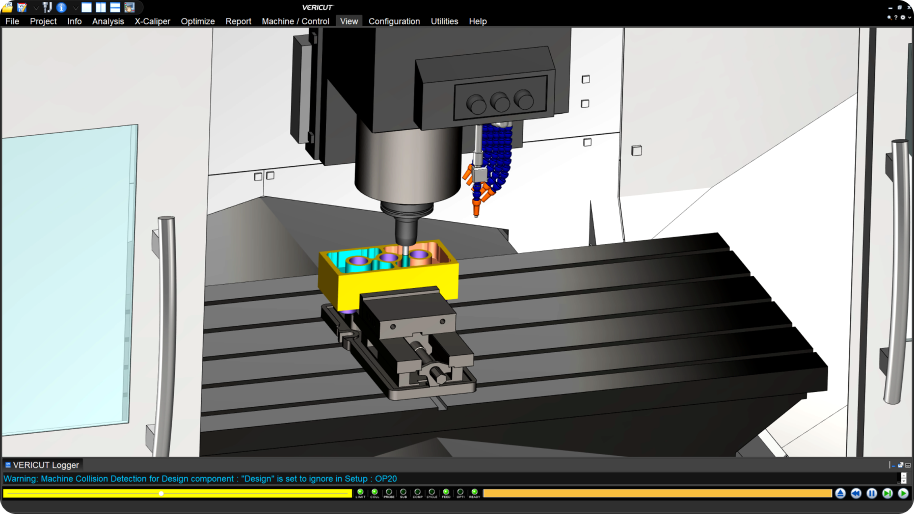

2.3. CAM for Simulation and Machining Verification

In CNC machining, even small errors can cause significant damage to tools or machines. CAM software specialized in simulation and verification helps businesses minimize risks, optimize toolpaths, and reduce production costs.

Key Features:

- Accurate simulation of the entire machining process

- Collision detection and error identification before actual machining

- Saves materials, tools, and reduces production incidents

Representative Software:

- VERICUT: Leading solution for simulation and verification, excels in collision detection and detailed toolpath analysis

- CIMCO: Popular for machining simulation and data management, strong support for CNC programming

- NC Simul: Strong in multi-axis machining simulation and feedrate optimization

2.4. CAM for Integrated Production and Enterprise Management

This category goes beyond machining, integrating full production process management—from planning and process preparation to operation and line optimization. It is ideal for large enterprises in aerospace, automotive, and mass production.

Key Features:

- Seamless integration between CAD – CAM – PLM

- Supports full production line simulation

- Helps optimize productivity and move toward smart manufacturing

Representative Software:

- DELMIA: Part of Dassault Systèmes ecosystem, strong in production simulation, line optimization, and enterprise-wide data management

- Siemens NX CAM: Deeply integrated with CAD/PLM, ideal for large-scale manufacturing

- HyperMill: Beyond multi-axis machining, also supports integration with manufacturing management systems

3. Benefits of Using CAM Software

Replacing manual CNC programming with CAM brings practical benefits. It saves engineers time, reduces errors, and serves as a crucial step in a company’s digital manufacturing transformation.

3.1. Automation and Faster Programming

Previously, engineers had to manually write each line of G-code—a time-consuming and error-prone task. CAM automatically generates toolpaths from CAD 3D models, reducing production preparation time and accelerating time-to-market.

3.2. High Precision and Reduced Errors

CAM can produce optimized toolpaths with micrometer-level precision. This ensures high-quality products, minimizes material waste, and reduces production errors—crucial for industries like automotive, aerospace, and medical.

3.3. Simulation and Verification Before Machining

CAM allows full process simulation on the computer before actual machining. Engineers can detect collisions, toolpath issues, or design inconsistencies, preventing costly errors such as damaged workpieces, broken tools, or CNC machine failure.

3.4. Cost and Resource Optimization

By optimizing toolpaths, CAM saves materials and cutting tools. Less trial-and-error and fewer reworks also mean lower machine operating and maintenance costs, enhancing business competitiveness.

3.5. Seamless Integration with Digital Production Chains

Modern CAM software integrates with CAD, CAE, and PLM, creating a continuous production process where design, machining, and verification data are synchronized—moving toward smart factory operations.

4. Applications of CAM in Modern Manufacturing

CAM is no longer just a tool for CNC programmers—it is essential for achieving precision, speed, and flexibility across industries. Its applications are increasingly widespread, especially in sectors demanding high quality and complex production.

4.1. Mechanical Engineering – Machine Building

CAM is used to manufacture machine parts, shafts, gears, gearboxes, and other mechanical components. It allows high-standard production and easy customization to meet different design requirements.

4.2. Mold Making and Plastics

In plastic injection or metal casting mold production, CAM handles curved surfaces, deep cavities, and intricate parts that manual programming cannot achieve. Specialized software like CAM-TOOL is the top choice for many companies.

4.3. Automotive and Aerospace

Both industries demand extreme precision and durability. CAM enables machining of engine components, turbine blades, car frames, and aerodynamic parts. Pre-simulation and verification are crucial to ensure safety and reduce risks.

4.4. Medical and Precision Equipment

In healthcare, CAM supports the production of implants, prosthetics, and surgical tools customized for each patient. It ensures absolute precision and shortens production time—vital for urgent medical cases.

4.5. Electronics and Consumer Products

Electronic components, plastic housings, and small metal parts can all be efficiently manufactured using CAM. Automation enables mass production with consistent quality, meeting high-volume consumer demand.

Conclusion

In modern manufacturing, CAM is not just a supporting tool—it is a key factor for improving efficiency, ensuring precision, and creating sustainable competitive advantage. Advanced solutions like CAM-TOOL, DELMIA, and VERICUT help manufacturers transform design ideas into reality while optimizing machining processes and product development.

👉 Contact NSV today to explore the right CAM solution, unlock your production potential, and achieve breakthroughs in every project.