CAM-TOOL / CADmeister / Excess Hybrid – Software Solutions for the Machining Industry

1. Manufacturing in the Era of Industry 4.0: New Demands, New Challenges

Today’s manufacturing industry faces more demanding requirements than ever: shorter product life cycles, increasingly complex components, and pressure to reduce costs while maintaining the highest quality.

In this context, modern CAM (Computer-Aided Manufacturing) and CAD/CAE technologies are no longer just support tools—they have become key factors in modern production processes.

With CAM, businesses can:

- Shorten the time from design to machining.

- Minimize errors and improve precision.

- Optimize costs through efficient use of materials and tooling.

Together with CAD/CAE platforms like CADmeister, which enable precise mold and part design and simulation, companies in Vietnam’s mold making, automotive, aerospace, and electronics sectors are increasingly enhancing their competitiveness. Among the most widely chosen tools, CAM-TOOL, CADmeister, and Excess Hybrid stand out for their expertise and ability to optimize the entire workflow from design to production.

2. CAM-TOOL – The Expert in Complex Mold Machining

CAM-TOOL is well-known in Japan and across many Asian countries for its ability to handle complex 3D molds.

Its greatest strength lies in its ability to generate smooth and stable toolpaths, producing nearly finished surfaces immediately after cutting. As a result, companies can significantly reduce polishing processes, which are often time- and cost-intensive.

For example, when machining an injection mold with intricate contours, CAM-TOOL calculates the optimal toolpath so that the cutting tool runs smoothly, minimizes wear, and shortens machining time while maintaining surface quality.

Beyond injection molds, CAM-TOOL is also widely applied in press dies, die casting molds, as well as precision automotive and aerospace parts.

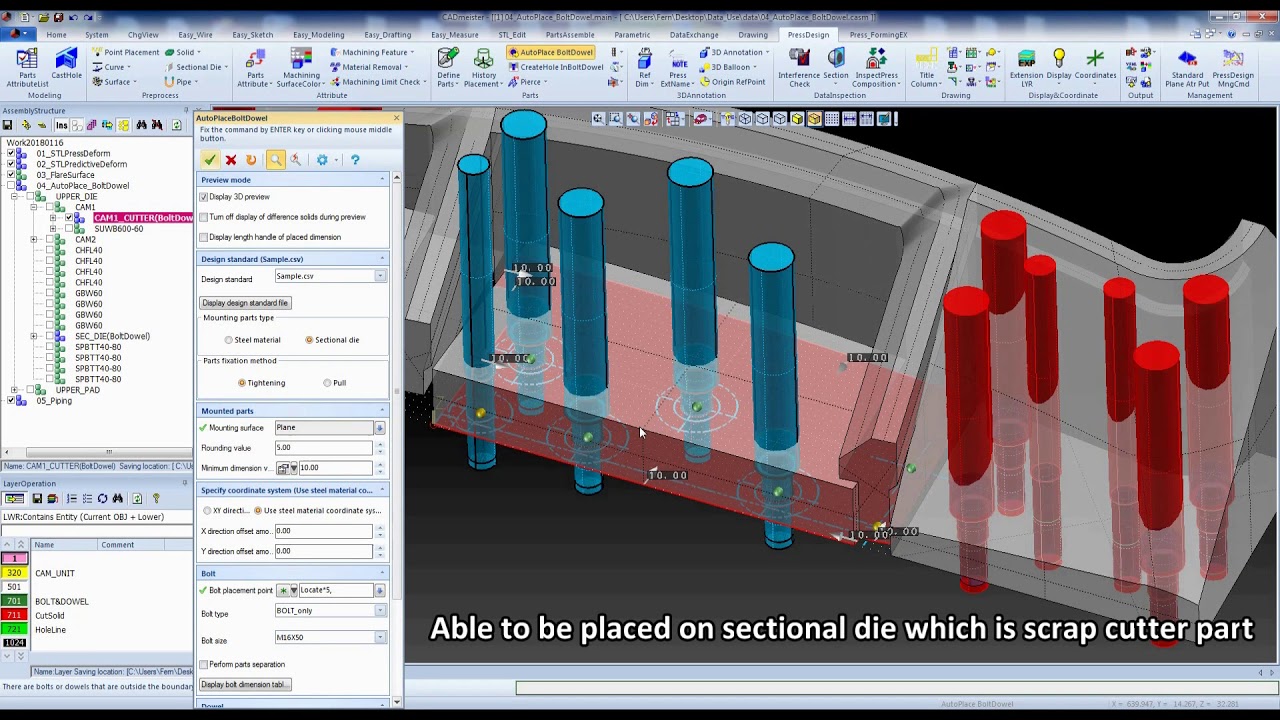

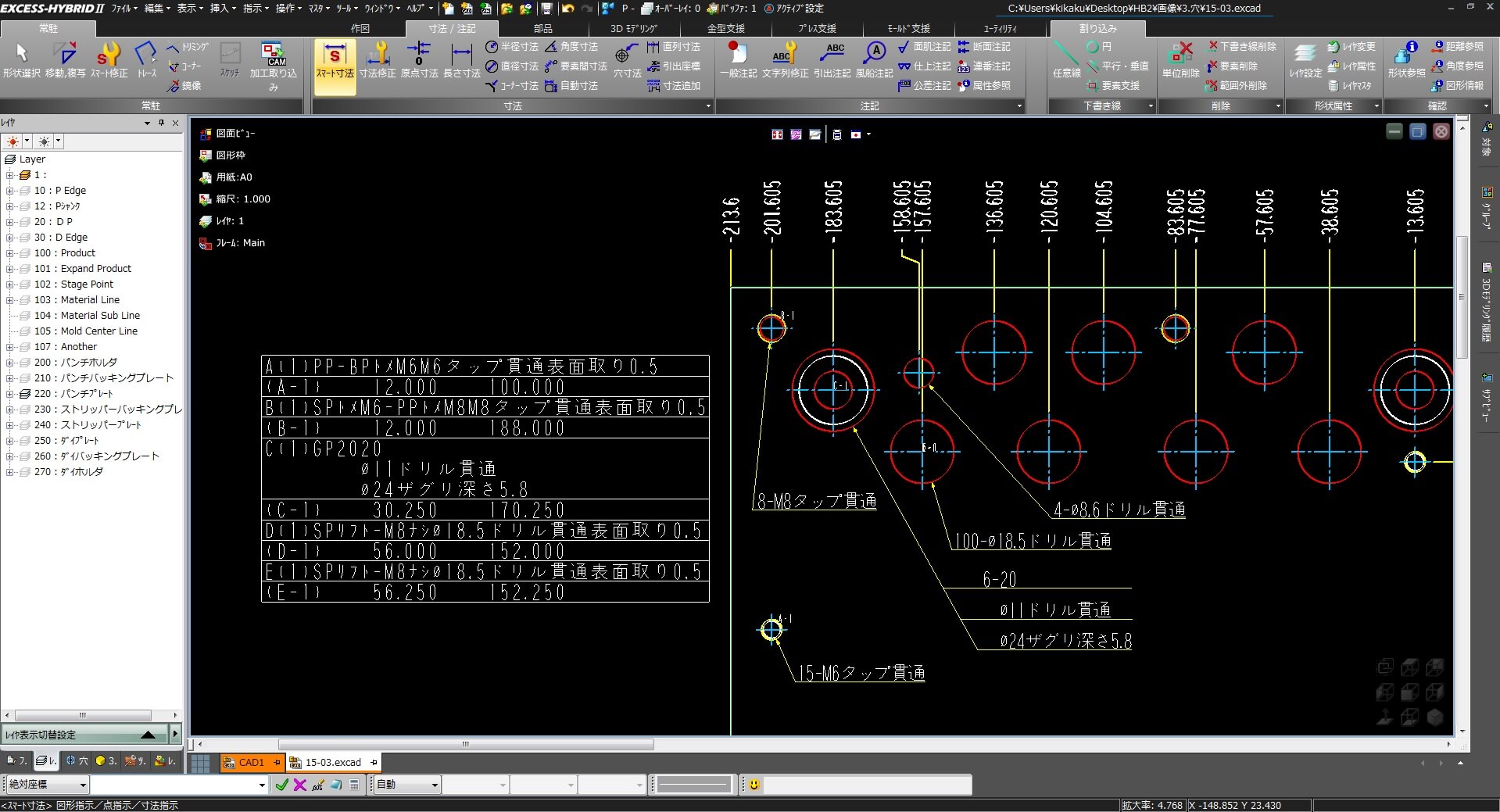

3. CADmeister – An Integrated CAD/CAM/CAE Ecosystem

Unlike CAM-TOOL, which focuses on machining, CADmeister offers a comprehensive solution from design to production.

With CADmeister, businesses can:

- Design products and molds directly in the software.

- Perform analysis and simulation (CAE) to predict problems before production.

- Program machining (CAM) on the same platform, minimizing data conversion risks.

The greatest benefit is seamless integration: from concept, design, and simulation to machining—all within one system, without relying on multiple software solutions. This is why CADmeister is trusted by many Japanese companies and suppliers in the automotive and electronics sectors, where precision and synchronization are absolutely critical.

4. Excess Hybrid – Where Speed Meets Stability

Excess Hybrid is a specialized CAM software designed to deliver exceptional machining speed while ensuring stability in deep cutting operations. With its Hybrid technology, it combines High-Speed Machining with the ability to maintain quality under the toughest machining conditions.

The result is a machining process that is not only significantly faster but also produces smooth, precise, and consistent surfaces. This is a crucial advantage in industries with strict surface quality requirements, such as mirror-finish mold production, aerospace components, and medical devices.

5. Each Tool – Its Own Unique Strength

You can think of it this way:

- CAM-TOOL is the “artisan” of machining, specialized in handling the most complex 3D surfaces with high precision.

- CADmeister is a “comprehensive ecosystem,” ensuring seamless flow from design and simulation (CAE) to CAM integration in production.

- Excess Hybrid is the “high-speed racer,” significantly reducing machining time without compromising surface quality or accuracy.

Therefore, no single software is the “best” for all cases. Businesses should consider their objectives and production specifics to select the right solution—or combine them for an optimal machining workflow.

6. Webinar: A Chance to Experience It Firsthand

As manufacturing shifts rapidly toward Smart Manufacturing, the application of CAM & CNC is no longer optional—it has become a prerequisite for boosting productivity, minimizing errors, and optimizing costs.

To support businesses, engineers, and managers in embracing this trend, NSV is hosting a Webinar:

“Applying CAM & CNC for Smart Manufacturing”

👉 Here, you will have the opportunity to:

- Get an overview of CNC programming & compare today’s popular CAM software.

- Discover & see live demos of key features of Parts CAM by CGS.

- Discover & see live demos of key features of CAM-TOOL by NSV.

- Join a live Q&A session with experts.

🎯 Don’t miss this chance to equip yourself with the knowledge and tools to lead in the smart manufacturing era.

[Register now to join the Webinar for free]

7. Conclusion

In today’s modern manufacturing environment, CAD/CAE and CAM are no longer just support tools—they have become key factors determining productivity, quality, and cost.

- CAM-TOOL: A specialized CAM solution, optimized for complex 3D mold machining.

- CADmeister: A comprehensive 3D CAD platform, integrating CAE and connecting to CAM, ensuring seamless workflow from design to production.

- Excess Hybrid: A powerful CAM software, combining high-speed and precise machining for molds and complex parts.

Mastering the strengths of each software and applying them flexibly helps businesses not only overcome current challenges but also enhance their competitive advantage for the future.

👉 Contact NSV today for consultation on the best CAD/CAM solutions for your business.