Comparison of CAD Software in the Manufacturing Industry

In the digital era, Computer-Aided Design (CAD) software plays a crucial role in modern manufacturing. Beyond just creating mechanical part drawings, CAD supports simulation, process optimization, and product lifecycle management. This enables businesses to accelerate product development, improve precision, and reduce production risks.

In the digital era, Computer-Aided Design (CAD) software plays a crucial role in modern manufacturing. Beyond just creating mechanical part drawings, CAD supports simulation, process optimization, and product lifecycle management. This enables businesses to accelerate product development, improve precision, and reduce production risks.

However, with the wide range of CAD software available today, selecting the right solution for your business size, industry, and development goals is not a simple task. In this article, we will analyze and compare the most popular CAD software used in manufacturing, helping you make an informed and effective decision.

1. Why Is Choosing the Right CAD Software So Important?

CAD is more than a drawing tool — it’s the backbone of the entire product development process: from ideation and design to simulation, manufacturing, and quality control. A suitable CAD solution can:

- Shorten product development time

- Ensure high precision in design

- Facilitate easy data sharing and collaboration

- Integrate seamlessly with simulation and manufacturing workflows

On the other hand, choosing the wrong software can lead to wasted time, resources, and high switching costs. That’s why understanding the strengths and limitations of each CAD tool is a critical first step toward optimizing your operational efficiency and sustainable growth.

2. Comparing the Most Common CAD Software in Manufacturing

2.1. CATIA – A Comprehensive Solution for Complex Products

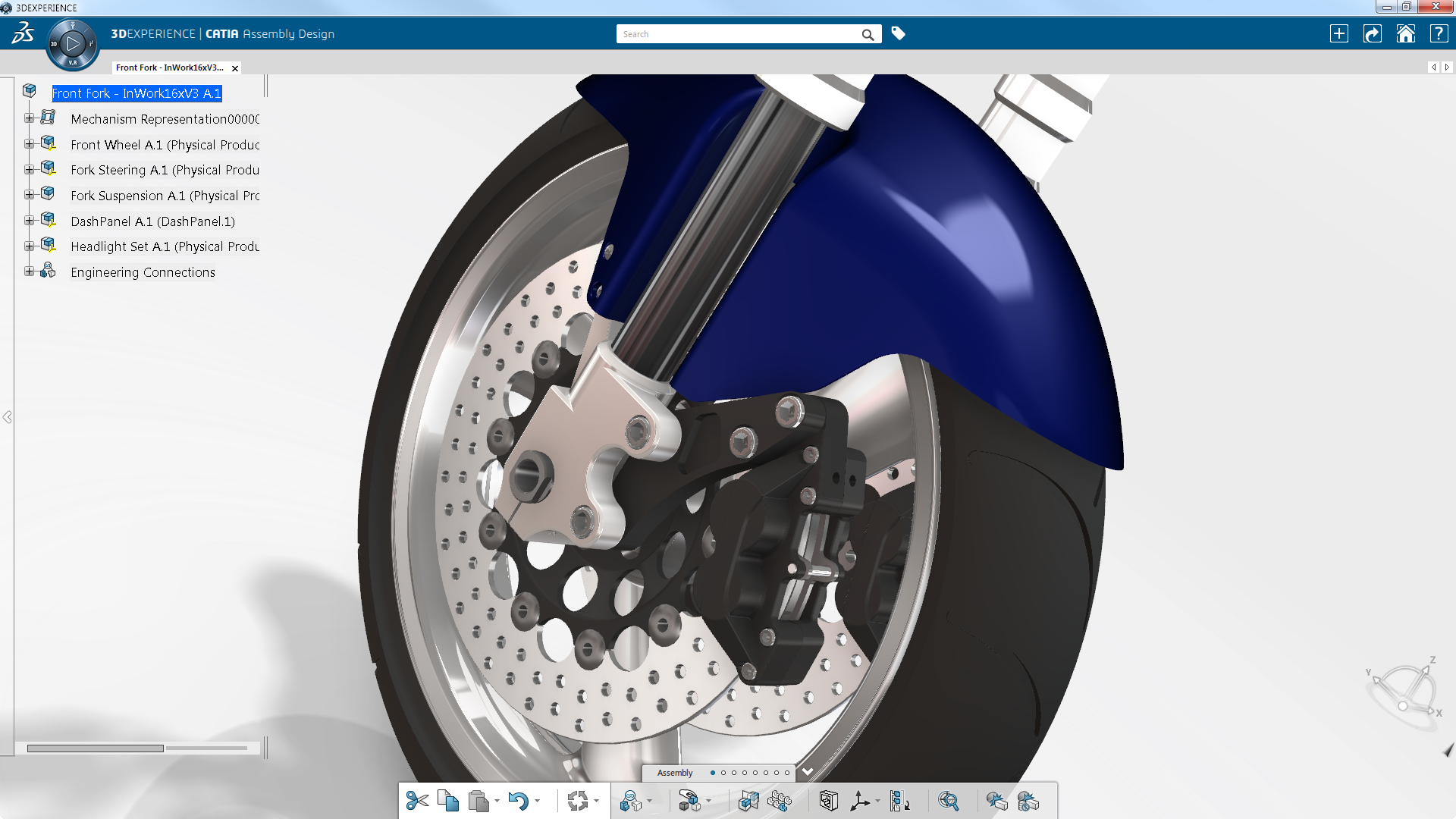

CATIA by Dassault Systèmes is a well-known software in industries such as automotive, aerospace, and industrial design. Renowned for its ability to create complex freeform 3D surfaces, CATIA also offers deep integration of CAE, CAM, and PLM modules through the 3DEXPERIENCE platform. This enables businesses to establish a seamless workflow from design to manufacturing and product lifecycle management.

In its latest version, CATIA, integrated with the 3DEXPERIENCE platform, fosters an interactive and collaborative environment between teams, rather than merely storing and sharing data. Notably, its built-in AI technology can analyze user actions and suggest the most suitable tools, optimizing workflow efficiency. This makes CATIA an ideal choice for OEMs and ODMs with high demands for precision, consistency, and collaboration. Although it requires advanced user skills, CATIA remains a top choice for companies seeking an end-to-end solution for design, manufacturing, and management.

2.2. Siemens NX – Strong in Integration and Advanced Simulation

Siemens NX excels at unifying the design–simulation–manufacturing chain within a single digital environment. It is well-suited for high-tech manufacturers and is widely used in precision-driven industries such as electronics, aerospace, and equipment production.

However, NX requires experienced engineers and robust technical infrastructure, making it more appropriate for enterprises with a mature engineering foundation.

2.3. SolidWorks – Popular, Easy to Learn, and Ideal for SMEs

SolidWorks is one of the most widely used 3D CAD software worldwide, especially among small and medium-sized enterprises. Its user-friendly interface, large support community, and rich plugin ecosystem help engineers design efficiently, produce accurate drawings, and collaborate effortlessly.

While it may not match CATIA or NX in advanced modeling or PLM integration, SolidWorks is a practical, effective choice for companies with limited budgets and simpler workflows.

2.4. Fusion 360 – Cloud-Based CAD for Startups and Freelancers

Fusion 360 by Autodesk offers an integrated CAD–CAM experience on the cloud. With tools for design, simulation, CNC programming, and online collaboration all in one platform, Fusion 360 is ideal for small engineering teams, startups, and freelancers.

Its strengths include low cost, flexibility, and the ability to work anywhere without needing high-end hardware. However, its capacity to handle complex models or deeply integrated systems is still more limited compared to higher-end solutions.

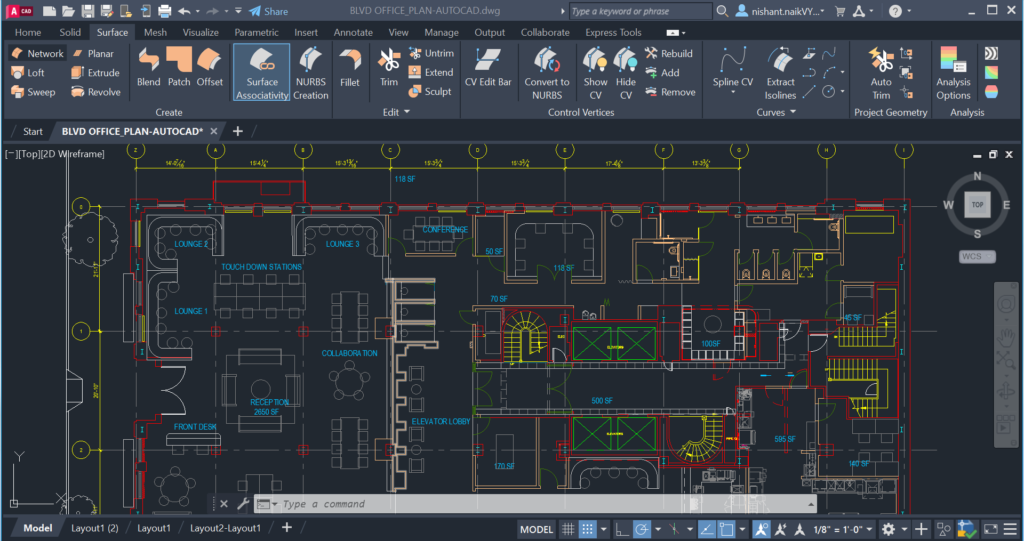

2.5. AutoCAD – The Standard for Traditional 2D Drafting

AutoCAD remains a cornerstone in technical 2D drafting, such as schematics, layouts, or simple components. While it’s not suited for advanced 3D product design, AutoCAD is still widely used in Vietnam due to its familiarity, ease of use, and broad file compatibility.

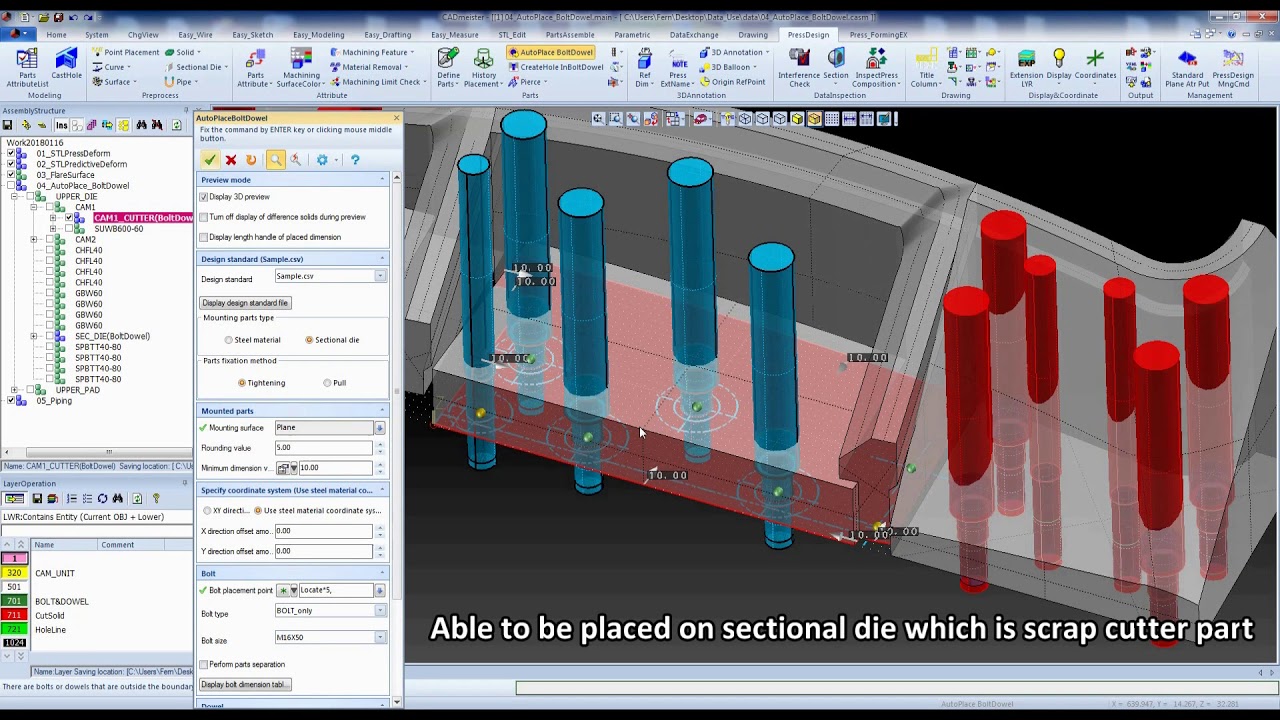

2.6. CADmeister – Specialized for Mold Design

CADmeister is a 3D CAD software focused on mold design and high-precision machining — areas that demand accuracy and optimization. With features for mold splitting, electrode design, interference analysis, and more, CADmeister helps reduce machining time, minimize errors, and improve production efficiency.

This software is especially suited for medium to large mold-making companies, or suppliers of plastic or metal parts in Japan and across Asia.

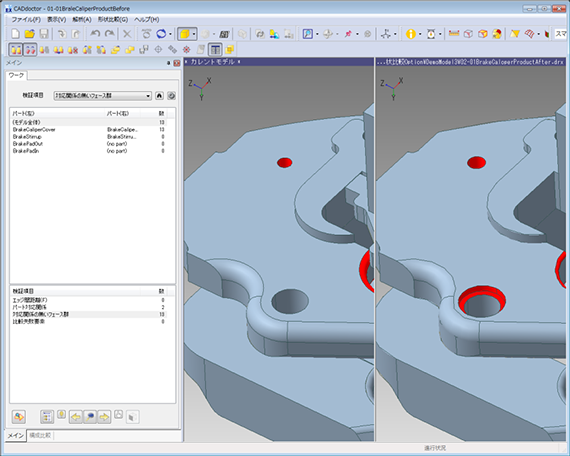

2.7. CADdoctor – Standardizing and Repairing CAD Data

When businesses deal with various CAD file formats from clients, partners, or suppliers, compatibility and geometry errors are inevitable. CADdoctor is a powerful tool for verifying, repairing, and converting CAD data, ensuring the imported models are clean and production-ready.

This makes CADdoctor ideal for manufacturing firms working with external data, where fast and reliable preprocessing is crucial before moving into CAM or simulation.

3. The Right CAD Software: Your First Step Toward Optimization

There is no one-size-fits-all CAD software — only the one best suited to your business goals, size, and industry needs.

If you are looking for:

- Comprehensive solution for design, simulation, and data management → CATIA is the leading enterprise solution

- User-friendly interface and easy to use for beginners → Siemens NX is a suitable choice

- An accessible, well-supported solution → SolidWorks is a safe choice

- A modern, flexible, low-cost environment → Fusion 360 is an ideal starting point

- Optimized mold design tools → CADmeister can significantly reduce time and labor

- Seamless CAD data standardization and cleanup → CADdoctor is indispensable

Whether you're a beginner engineer or a growing manufacturer, choosing the right CAD software is the first step to accelerating success. Contact us today for personalized consultation and hands-on demos tailored to your actual needs — and start optimizing your design and production processes with confidence.