Phần mềm CAM cho gia công chính xác cao: Đâu là lựa chọn tối ưu?

Trong ngành sản xuất hiện đại, độ chính xác không chỉ là một lợi thế, mà còn là điều kiện tiên quyết. Từ lĩnh vực hàng không vũ trụ, y tế, cho đến chế tác khuôn mẫu, sai số dù chỉ vài micromet cũng có thể dẫn đến sản phẩm lỗi, lãng phí nguyên liệu hoặc thậm chí gây rủi ro an toàn.

1. Vì sao gia công chính xác cao cần đến CAM?

Trong ngành sản xuất hiện đại, độ chính xác không chỉ là một lợi thế, mà còn là điều kiện tiên quyết. Từ lĩnh vực hàng không vũ trụ, y tế, cho đến chế tác khuôn mẫu, sai số dù chỉ vài micromet cũng có thể dẫn đến sản phẩm lỗi, lãng phí nguyên liệu hoặc thậm chí gây rủi ro an toàn.

Đây chính là lúc phần mềm CAM (Computer-Aided Manufacturing) phát huy vai trò. CAM là cầu nối giữa thiết kế CAD và máy CNC, giúp tạo đường chạy dao tối ưu, mô phỏng quá trình cắt gọt, giảm thiểu sai sót và đảm bảo sản phẩm cuối cùng đạt đúng yêu cầu kỹ thuật.

2. Tiêu chí chọn phần mềm CAM cho gia công chính xác cao

Khi cân nhắc lựa chọn phần mềm CAM, doanh nghiệp và kỹ sư thường chú ý đến những yếu tố sau:

- Hỗ trợ đa trục (3–5 axis, thậm chí Swiss-type): xử lý được chi tiết phức tạp, nhiều bề mặt cong.

- Khả năng mô phỏng & tránh va chạm: phát hiện lỗi trước khi đưa vào máy thật.

- Tạo đường chạy dao thông minh: công nghệ adaptive clearing, iMachining… giúp tiết kiệm thời gian và tăng tuổi thọ dao cụ.

- Khả năng tích hợp với CAD/PLM: quy trình thiết kế – chế tạo liền mạch, hạn chế lỗi dữ liệu.

- Độ ổn định, cộng đồng & hỗ trợ kỹ thuật: càng nhiều người dùng, càng dễ tìm giải pháp khi gặp sự cố.

3. Các lựa chọn CAM nổi bật trên thị trường

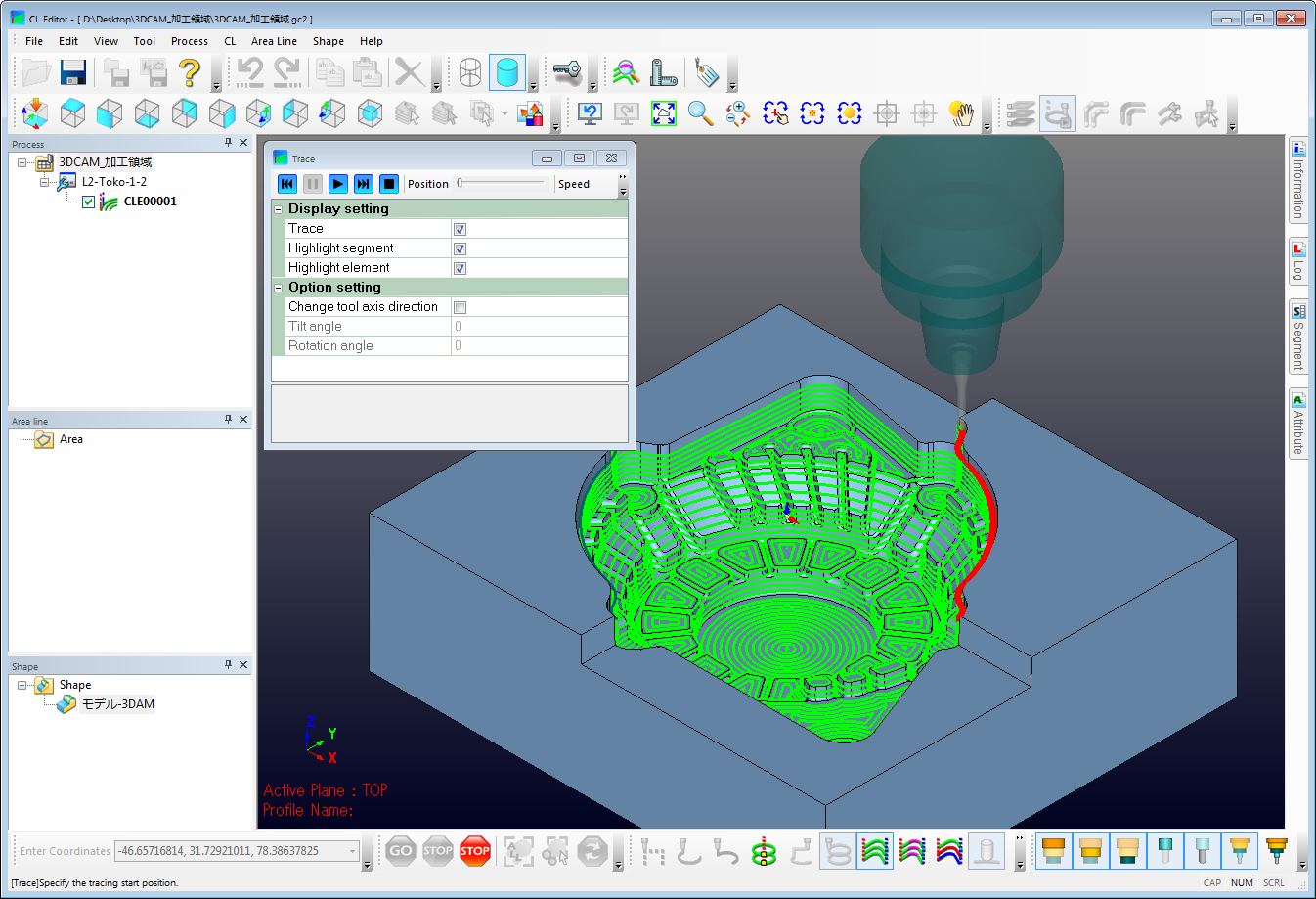

3.1 CAM-TOOL – Gia công độ chính xác cao

CAM-TOOL là phần mềm CAM nổi tiếng đến từ Nhật Bản, chuyên cho gia công khuôn mẫu và linh kiện có yêu cầu độ chính xác cao. Với thuật toán tính toán đường dao độc đáo, CAM-TOOL tạo ra bề mặt mượt, giảm thiểu sai sót và rút ngắn đáng kể thời gian xử lý.

Các chiến lược đường dao tốc độ cao (HSM) giúp nâng cao chất lượng bề mặt, đồng thời giảm thiểu công đoạn đánh bóng thủ công. Phần mềm này đặc biệt phù hợp cho các nhà sản xuất khuôn nhựa, khuôn dập kim loại và chi tiết tinh xảo trong ngành điện tử. Dù vậy, giao diện và cách thao tác của CAM-TOOL vẫn mang phong cách “truyền thống”, nên người dùng có thể cần thêm thời gian để làm quen.

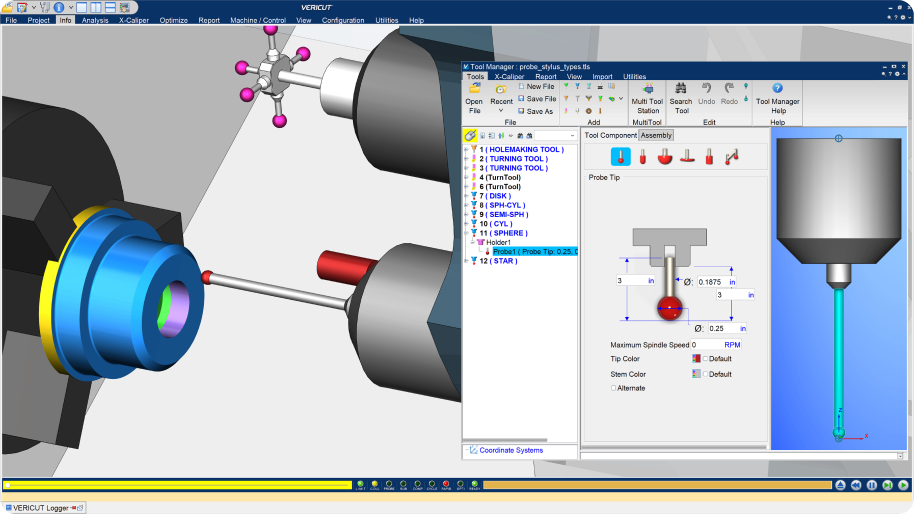

3.2 VERICUT – An toàn và kiểm chứng đường dao

VERICUT là phần mềm chuyên về mô phỏng và kiểm tra đường dao, giúp phát hiện va chạm, tối ưu thời gian chạy máy và đảm bảo an toàn trong gia công. Đây là lựa chọn quen thuộc của nhiều doanh nghiệp sản xuất chi tiết có giá trị cao hoặc gia công 5 trục.

Vì không phải là giải pháp CAM độc lập, VERICUT thường được sử dụng song song với một phần mềm CAM khác, đóng vai trò như một công cụ khách quan để kiểm chứng và tối ưu chương trình gia công.

3.3 DELMIA Machining Software – CAM tích hợp cho sản xuất thông minh

DELMIA Machining Software là giải pháp CAM mạnh mẽ trong nền tảng 3DEXPERIENCE của Dassault Systèmes, cho phép lập trình, mô phỏng và tối ưu gia công trên nhiều loại máy CNC, từ 3 trục đến 5 trục phức tạp. Các chiến lược gia công tiên tiến giúp nâng cao chất lượng bề mặt và rút ngắn thời gian lập trình.

Điểm nổi bật của DELMIA không chỉ ở năng lực CAM, mà còn ở khả năng kết nối liền mạch với dữ liệu thiết kế và quy trình sản xuất. Nhờ vậy, doanh nghiệp vừa tận dụng được sức mạnh gia công, vừa quản lý toàn diện quá trình sản xuất trên một nền tảng thống nhất.

3.4 Mastercam – Phổ biến và dễ áp dụng

Mastercam là một trong những phần mềm CAM được sử dụng rộng rãi nhất trên thế giới, nổi bật nhờ tính thân thiện và hệ sinh thái hỗ trợ đa dạng. Phần mềm cung cấp đầy đủ tính năng gia công từ 2.5D, 3D đến 5 trục, giúp các xưởng cơ khí dễ dàng triển khai nhanh chóng.

Mastercam phù hợp với các doanh nghiệp vừa và nhỏ muốn áp dụng CAM mà không mất quá nhiều thời gian đào tạo. Tuy vậy, với những yêu cầu lập trình phức tạp hơn, doanh nghiệp có thể cần bổ sung thêm các module mở rộng.

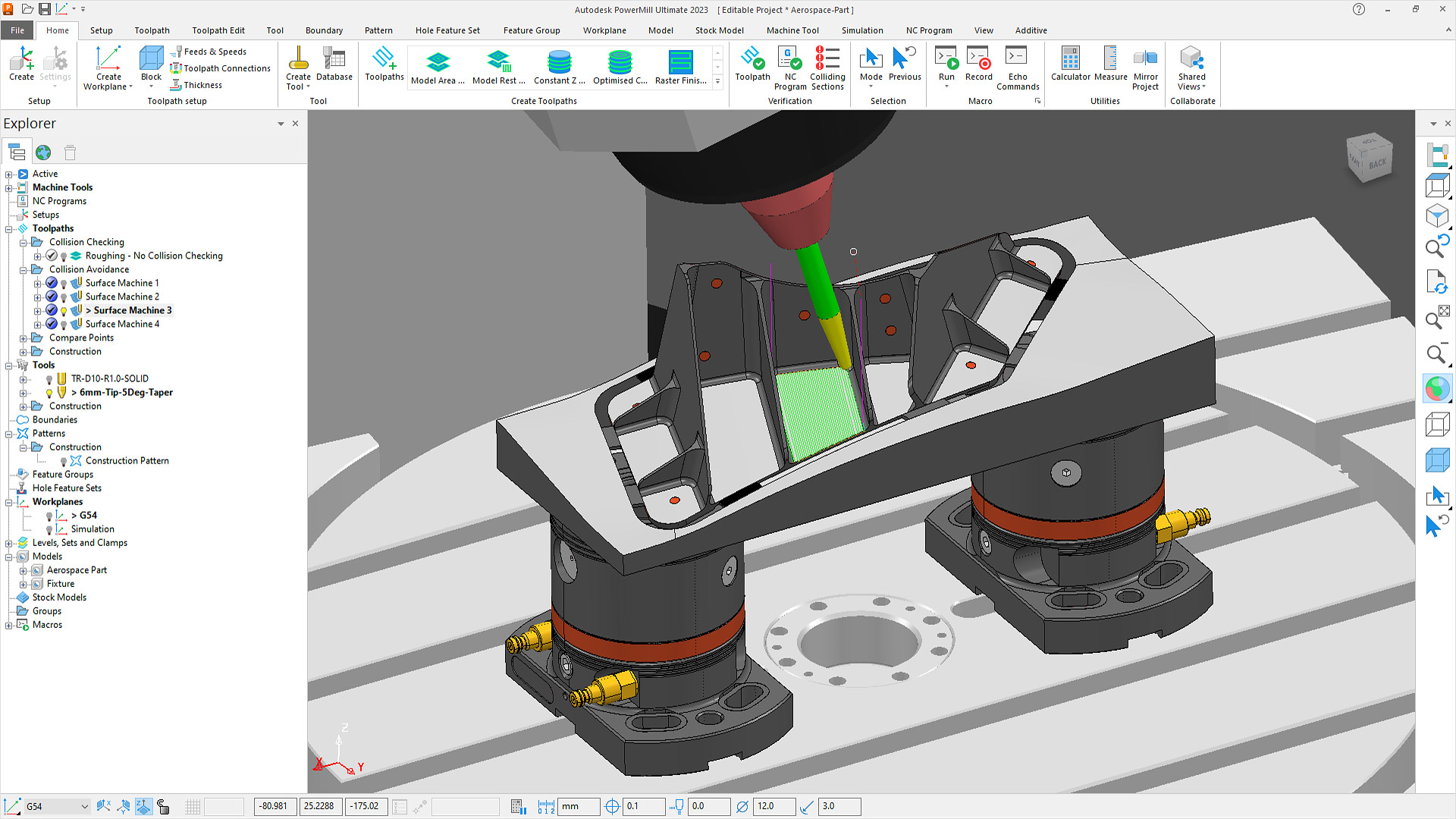

3.5 PowerMILL – Chuyên sâu cho khuôn mẫu

PowerMILL được sử dụng nhiều trong gia công khuôn mẫu và bề mặt cong. Các chiến lược gia công tốc độ cao (HSM) hỗ trợ cải thiện chất lượng bề mặt, đồng thời giúp giảm bớt công đoạn hoàn thiện thủ công.

Phần mềm này đặc biệt phù hợp cho các nhà sản xuất khuôn mẫu trong ngành nhựa và kim loại. Tuy nhiên, PowerMILL chủ yếu mạnh ở lĩnh vực khuôn mẫu, nên có thể chưa thật sự tối ưu nếu mục tiêu là sản xuất hàng loạt.

3.6 hyperMILL – Linh hoạt cho gia công 5 trục

hyperMILL được biết đến với khả năng xử lý tốt các chi tiết phức tạp trên nhiều trục, đặc biệt là 5 trục. Phần mềm cung cấp nhiều chiến lược gia công khác nhau, hỗ trợ nâng cao độ chính xác và năng suất.

Giải pháp này phù hợp cho doanh nghiệp muốn tối ưu quá trình gia công phức tạp. Tuy nhiên, do tập trung nhiều vào khả năng lập trình 5 trục nên người mới có thể cần thêm thời gian làm quen để khai thác tối đa.

4. Chọn phần mềm CAM phù hợp – chìa khóa cho gia công chính xác cao

Mỗi phần mềm CAM đều có thế mạnh riêng, không có lựa chọn nào hoàn hảo cho tất cả. Quan trọng là tìm ra giải pháp phù hợp nhất với quy trình và định hướng của doanh nghiệp bạn

- DELMIA: phù hợp với doanh nghiệp hướng tới chuyển đổi số toàn diện, quản lý đồng bộ từ thiết kế đến gia công.

- CAM-TOOL : giải pháp tối ưu cho khuôn ép nhựa, khuôn dập và các chi tiết cần độ chính xác cao.

- VERICUT : chuẩn mực trong mô phỏng và kiểm soát lỗi, giúp tiết kiệm chi phí và bảo vệ máy móc.

- PowerMILL: lựa chọn quen thuộc cho các xưởng khuôn chuyên sâu, đặc biệt trong gia công 5 trục.

- hyperMILL: giải pháp CAM hiện đại, mang lại sự linh hoạt cho nhiều ngành sản xuất.

- Mastercam: phổ biến, dễ tiếp cận, phù hợp cho nhiều quy mô sản xuất và ngành công nghiệp khác nhau.

Kết luận

Điều quan trọng nhất là doanh nghiệp cần xác định rõ nhu cầu và định hướng phát triển để lựa chọn công cụ phù hợp. Khi chọn đúng phần mềm CAM, bạn không chỉ rút ngắn thời gian gia công mà còn tạo nền tảng vững chắc cho khả năng cạnh tranh trong tương lai.

👉 Nếu bạn đang cân nhắc lựa chọn, hãy liên hệ với NSV chúng tôi để được tư vấn giải pháp CAM phù hợp nhất cho doanh nghiệp của bạn.